3D Printing Introduction

01 Mar 2022

Introduction – What is 3D printing?

3D Printing is a process for making a physical object from a three-dimensional digital model, typically by laying down many successive thin layers of material. It brings a digital object (its CAD representation) into its physical form by adding layer by layer of materials.

3D Printing Technology is Additive Manufacturing Process.

Additive Manufacturing Process is a process in which 3D object is completed by means of depositing (adding) a physical material in form of layers whereas, in traditional Subtractive Manufacturing activity, the process is completed by means of successively removing/cutting the physical material to make a 3D object.

Subtractive manufacturing can be done by manually cutting the material but is most typically done with a CNC Machine.

3D Printing Process

3D Printing process begins with a computer model (CAD) design - the blueprint of the physical object. Later this CAD design file is sliced into thin layers by software provided with 3D Printer machine. These layers are very thin and 2-dimensional, laying down successively makes a complete 3D object. The file with this layer instructions generated by the software is called G-code used as instruction-set for 3D Printer.

From here-on 3D Printer works as per its process.

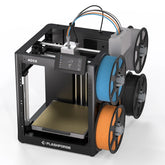

3D Printers use multiple processes viz. FDM (Fused Deposition Modelling), SLA (Stereolithography), SLS (Selective Laser Sintering), DLP (Digital Light Processing), SLM (Selective Laser Melting) ..etc

Among all these methods - FDM, SLA and DLP are widely used in industries and consumer applications also.

All these processes use a different type of raw material as input -

FDM uses Filament plastic for melting and printing layer

SLA & DLP uses Resin liquid

Large scale industrial SLS 3D Printer uses a laser to melt (sinter) thin layer of metal or plastic in powder form.

This wide range of materials provides a wide scope to use 3D Printing technology in Industrial Manufacturing, Automotive, Medical, Healthcare, Education, Robotics, Jewellery, Arts, Gift & Decor, Food and many more.

Now Gcode will be processed by 3d printer using 3d printing material to make a 3d object as per the process. Time for 3d printing an object may vary as per technology and 3d printer specification.

3D Printing vs. Traditional Manufacturing

3D Printing is a great tool for manufacturing custom jobs for prototyping & testing before mass production or for even very small requirements.

When compared with other traditional manufacturing methods like subtractive (CNC) or formative (Injection Moulding) manufacturing technology, additive manufacturing technology (3D Printing) is a low cost and quick turnaround time option. 3D Printing is a very efficient cost and time-wise in cases where one or very few parts are required.

3D Printing can produce prototypes very quickly at a low-cost by eliminating high-cost setup requirements of the traditional manufacturing process. This special advantage compared to traditional manufacturing for prototype & testing job work makes 3D Printing technology goto solutions at many industries.

3D Printing Application

3D Printing also referred to as "Rapid Prototyping" technology is now being used in almost all industrial verticals as prototyping tool and small scale manufacturing setups also.

Here is a quick list of a few application references:

1.) Medical and Dental

3D printing technologies are being used for making prototypes to support new product development for the medical healthcare and dental industries, the technologies are also utilized to make patterns for the downstream metal casting of dental crowns and in the manufacture of tools over which plastic is being vacuum-formed to make dental aligners.

2.) Aerospace

Aircraft development is very critical in nature, the R&D process and standards are very demanding & high-end. For this industrial-grade 3D printing systems are solutions. Over the years 3D Printing Process and new-age 3D Printing materials development have seen a number of key applications developed for the aerospace sector — and some non-critical parts are all-ready flying on aircraft.

3.) Automotive

4.) Jewellery

5.) Art / Design / Sculpture

6.) Architecture

7.) Fashion

8.) Food

9.) Consumer

3D Printing is a process for making a physical object from a three-dimensional digital model, typically by laying down many successive thin layers of material. It brings a digital object (its CAD representation) into its physical form by adding layer by layer of materials.

3D Printing Technology is Additive Manufacturing Process.

Additive Manufacturing Process is a process in which 3D object is completed by means of depositing (adding) a physical material in form of layers whereas, in traditional Subtractive Manufacturing activity, the process is completed by means of successively removing/cutting the physical material to make a 3D object.

Subtractive manufacturing can be done by manually cutting the material but is most typically done with a CNC Machine.

3D Printing Process

3D Printing process begins with a computer model (CAD) design - the blueprint of the physical object. Later this CAD design file is sliced into thin layers by software provided with 3D Printer machine. These layers are very thin and 2-dimensional, laying down successively makes a complete 3D object. The file with this layer instructions generated by the software is called G-code used as instruction-set for 3D Printer.

From here-on 3D Printer works as per its process.

3D Printers use multiple processes viz. FDM (Fused Deposition Modelling), SLA (Stereolithography), SLS (Selective Laser Sintering), DLP (Digital Light Processing), SLM (Selective Laser Melting) ..etc

Among all these methods - FDM, SLA and DLP are widely used in industries and consumer applications also.

All these processes use a different type of raw material as input -

FDM uses Filament plastic for melting and printing layer

SLA & DLP uses Resin liquid

Large scale industrial SLS 3D Printer uses a laser to melt (sinter) thin layer of metal or plastic in powder form.

This wide range of materials provides a wide scope to use 3D Printing technology in Industrial Manufacturing, Automotive, Medical, Healthcare, Education, Robotics, Jewellery, Arts, Gift & Decor, Food and many more.

Now Gcode will be processed by 3d printer using 3d printing material to make a 3d object as per the process. Time for 3d printing an object may vary as per technology and 3d printer specification.

3D Printing vs. Traditional Manufacturing

3D Printing is a great tool for manufacturing custom jobs for prototyping & testing before mass production or for even very small requirements.

When compared with other traditional manufacturing methods like subtractive (CNC) or formative (Injection Moulding) manufacturing technology, additive manufacturing technology (3D Printing) is a low cost and quick turnaround time option. 3D Printing is a very efficient cost and time-wise in cases where one or very few parts are required.

3D Printing can produce prototypes very quickly at a low-cost by eliminating high-cost setup requirements of the traditional manufacturing process. This special advantage compared to traditional manufacturing for prototype & testing job work makes 3D Printing technology goto solutions at many industries.

3D Printing Application

3D Printing also referred to as "Rapid Prototyping" technology is now being used in almost all industrial verticals as prototyping tool and small scale manufacturing setups also.

Here is a quick list of a few application references:

1.) Medical and Dental

3D printing technologies are being used for making prototypes to support new product development for the medical healthcare and dental industries, the technologies are also utilized to make patterns for the downstream metal casting of dental crowns and in the manufacture of tools over which plastic is being vacuum-formed to make dental aligners.

2.) Aerospace

Aircraft development is very critical in nature, the R&D process and standards are very demanding & high-end. For this industrial-grade 3D printing systems are solutions. Over the years 3D Printing Process and new-age 3D Printing materials development have seen a number of key applications developed for the aerospace sector — and some non-critical parts are all-ready flying on aircraft.

3.) Automotive

4.) Jewellery

5.) Art / Design / Sculpture

6.) Architecture

7.) Fashion

8.) Food

9.) Consumer

Sample Block Quote

Praesent vestibulum congue tellus at fringilla. Curabitur vitae semper sem, eu convallis est. Cras felis nunc commodo eu convallis vitae interdum non nisl. Maecenas ac est sit amet augue pharetra convallis.

Sample Paragraph Text

Praesent vestibulum congue tellus at fringilla. Curabitur vitae semper sem, eu convallis est. Cras felis nunc commodo eu convallis vitae interdum non nisl. Maecenas ac est sit amet augue pharetra convallis nec danos dui. Cras suscipit quam et turpis eleifend vitae malesuada magna congue. Damus id ullamcorper neque. Sed vitae mi a mi pretium aliquet ac sed elitos. Pellentesque nulla eros accumsan quis justo at tincidunt lobortis deli denimes, suspendisse vestibulum lectus in lectus volutpate.